- Freedom from Calibration: When your analyzer is based on fundamental rules of science, like the electrolytic principle, there is no need for calibration! Consider the savings, right there, on time, labor, and materials, like calibration gases.

- Freedom from Drift: We hear all the time about analyzers that purchasers love for their low up-front cost, but that create costly headaches in the field. That’s because drift-prone equipment calls for frequent calibration, leading to a high Cost-of-Ownership and process interruption. Such factors do not always go into engineering and purchasing decisions, unfortunately. But, they are a source of chronic pain, down-time, and expense in actual use.

- Greater Safety: Oftentimes, technicians’ roles are high turnover, potentially resulting in folks who may lack both experience and, sometimes, adequate training. This increases the chance of hazardous errors when they are moving and handling calibration gases. Not only that, but more and more facilities are in remote locations where trained technicians are just plain hard to find. More, frequent calibrations interfere with automating gas plant operation, which many gas producers now seek.

- Confidence in Your Gas: Whether you are a maker or user of industrial, natural, or specialty gases, there is, frankly speaking, great comfort in knowing that your gas is certified by reliable, repeatable, and precise technology that is proven and validated by the world’s leading metrology labs. At MEECO, we are honored serve the most demanding and sensitive applications, including medical gas, semiconductor manufacturing, and space research.

Principle of Operation:

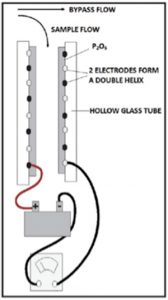

Based on Faraday’s Law of Electrolysis, MEECO’s technology electrolyzes moisture at fractional parts-per-million or parts-per-billion (ppm or ppb). As the gas flows into the analyzer, 100% of the sample moisture is absorbed by a phosphorus pentoxide (P2O5) film that covers two spirally-wound electrodes embedded inside a hollow glass tube (the cell). By applying an electrical potential (voltage) to the electrodes, each absorbed water molecule is split, generating a finite current. This current is precise and proportional to the amount of electrolyzed water. With a known flow rate and known cell volume, this provides a direct measurement of the water vapor present in the sample gas.

Use our handy Delta Flow Test:

Requirement: Nitrogen or other inert sample gas, with a stable moisture concentration higher than the analyzer’s low detection limit. Ideally, the moisture concentration will be close to the middle of the analyzer’s operating range.

Five easy steps:

Example:

Delta Flow Diagnostics:

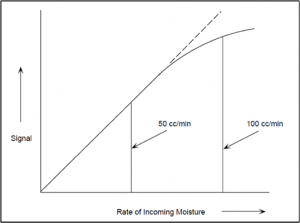

Over-range -> Cell Saturation and Possibility of Wash-out. If the electrolytic cell is hit by moisture beyond its upper measurement range, it can saturate the thin phosphoric acid film and, thus, fail to absorb and electrolyze properly. In such a case, as shown in Figure 1 (pictured right), the electrolysis signal is no longer proportional to the level of incoming moisture. The response curve flattens and continues toward a saturation value for very high concentrations. Here, the reading at 100 cc/minute is too low while the 50 cc/minute reading is not affected. Thus, 100 cc/minute reading will NOT be twice the 50 cc/minute reading.

Had the test been conducted at a lower concentration within the operating range, the 100 cc/minute reading would be approximately twice the 50 cc/minute reading, based on the linear scope of response.

When the cell is factory-qualified, a certificate of calibration is issued, with a full two-year life. The cell is also covered under a two-year warranty when it is operated within its range in accordance with proper procedures. (Please reference your operator manual.)

| CELL (SQUARE BODY) | ANALYZER | APPLICATION |

|---|---|---|

| AHLR | AquaVolt+ | Hydrogen & Inert Gas |

| AILR | AquaVolt+ | Inert Gas Only |

| AOLR | AquaVolt+ | Oxygen, CO₂ & Inert Gas |

| AOLR-I | AquaVolt+ | Inert Gas |

| RILR | Tracer 2 | Inert Gas Only |

| RTLR | Tracer 2 | Oxygen, Hydrogen & Inert Gas |

| RILR ♥ Cell | Tracer 2 | Inert Gas Only |

| RTLR ♥ Cell | Tracer 2 | Oxygen, Hydrogen & Inert Gas |

| CELL (ROUND BODY) | ANALYZERS | APPLICATION |

| AP | Industrial | Sweet Natural Gas |

| AP 10CC | Industrial | Sweet Natural Gas |

| APO | Industrial | Oxygen & Inert Gas |

| APO 10CC | Industrial | Oxygen & Inert Gas |

| APO-I | Industrial | Air & Inert Gas |

| APR | Natural Gas | Sour Natural Gas & Inert Gas |

| APR 10CC | Natural Gas | Sour Natural Gas & Inert Gas |

| APRH | Industrial | Hydrogen & Inert Gas |

| APRH 10CC | Industrial | Hydrogen & Inert Gas |

| Cl2 | Industrial | Chlorine Gas |

| HSPR | Industrial | Refrigerant Gas |

| Gas Type | Tracer 2 Cell Range |

|---|---|

| Oxygen | 0 – 1200 ppb |

| Hydrogen | 0 – 500 ppb |

| Inerts | 0 – 2000 ppb |

* Please consult factory or your local MEECO representative for special applications.