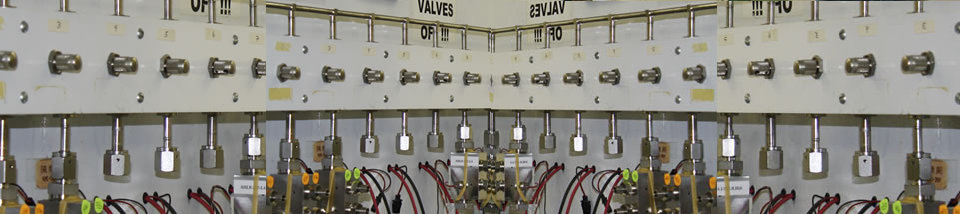

Newly designed electrolytic moisture transducers address five key needs for continuous, online analysis. The MEECO Accupoint transducers include:

- Improved long term accuracy.

- Greater contamination resistance.

- Multi-point capability.

- Intrinsic Safety design.

- Low cost.

Although these features are important for all moisture measurement applications, they are particularly critical for continuous online and multi-point use, says MEECO’s Dr. Lance D. Silverman. To appreciate how the design of the new transducers addresses these needs, it is valuable to review the basis of the electrolytic method.

The electrolytic method

An electrolytic moisture sensor functions by absorbing and electrolyzing all of the water from a controlled flow of sample gas. The resulting electrolysis current is an absolute measure of the amount of moisture entering the detector by Faraday’s Law: every water molecule that is electrolyzed produces two electrons in the detector circuit. The instrument does not need to be calibrated against a moisture standard.

This is particularly important for on-line applications, where recalibration interrupts service and proves costly. Instruments requiring calibration also give erroneous results unless calibrated frequently.

Contamination resistance is especially significant for on-line instruments that are continuously in service. All moisture detectors, whether electrolytic or other types, are affected by contaminants in natural gas. Contaminants, such as glycols, amines, and particulates, shorten cell life, particularly in very dirty gas. Filters are commonly used on analyzers to reduce contamination.

New transducer design

The new electrolytic moisture transducers address the special needs for on-line use through three innovations:

- An orifice-based flow system for improved long-term accuracy.

- Reduced sample flow for greater contamination resistance with no response time loss.

- Four- to 20-mA loop-power electronic design for multipoint capability and intrinsic safety.

These also contribute to lower cost and maintenance requirements.

Orifice-based flow system

The electrolytic method, based on Faraday’s Law, requires control of the sample flow through the cell. The Accupoint transducer uses an orifice-based flow system to give accurate flow control at low cost. A dual-stage pressure regulator maintains a stable pressure in the instrument. Downstream of the electrolytic cell, a sapphire orifice controls sample flow through the cell. Adjustment of the pressure accurately sets this flow to 10 sccm. A second, larger orifice controls the less critical bypass flow rate at a liter per minute.

The flow system design offers excellent long-term accuracy for low cost. Alternative flow control methods include mass flow controllers, with high cost and extensive electronic requirements. On the other hand, their larger, movable parts and O-rings make needle valves for flow control less stable than sapphire orifices. In fact, the orifice flow control system is so stable, Silverman says, that it can accurately maintain very low flows – 10 sccm – to reduce contamination effects.

Contamination resistance

In both academic studies and commercially, electrolytic hygrometers were traditionally used with a sample flow rate through the cell of 100 sccm. This appeared optimum, since a lower flow reduced sensitivity (less water enters the cell per minute). By contrast, a higher flow may not allow complete absorption of water from the sample.

Recent studies at MEECO show that much lower cell flow rates, just 10 sccm rather than 100, can serve natural gas applications without loss of sensitivity or response time. This reflects two important design features: (1) cell materials that do not absorb moisture and (2) a high ratio of bypass to sample flow rates. The use of lower flow rates greatly increases contamination resistance and cell life by reducing the amount of contaminants entering the cell by 90%.

Because contaminants enter the cell at only one-tenth the rate, cell life can be extended 10 fold by reduction of flow to 10 sccm. Field studies of Accupoint transducers with 10-sccm sample flow confirm that cell life is extended by this magnitude. Thus you greatly reduce the need to change cells for cleaning and resensitizing, Silverman says.

Laboratory studies comparing response time at 10- versus 100-sccm sample flow show that response time is independent of flow when switching from dry to gas wet at 7 #/MMSCF. For both cell flows, the transducer reached 50% of final response in less than two minutes and 90% of final response in less than five minutes. Drying time was also impervious to sample flow. Instruments dried to below 1 #/MMSCF in less than five minutes in both cases.

Multipoint Capability

Designed as a 4- to 20-mA loop-powered transducer, the Accupoint makes the electrolytic method simpler, less expensive, and better suited to multipoint on-line use, according to Silverman. You can control several transducers using the controller of your choice. Each transducer is powered by a 24-volt loop (12 to 36 volts are acceptable). The instrument returns a 4-to 20- mA signal proportional to the measured moisture. The transducers are designed for intrinsic safety.

Accupoint transducers use the electrolytic method to measure moisture in natural gas. A new orifice-based flow system improves long-term accuracy, while allowing reduced flow for contamination control. Laboratory and field studies show that reduced flow (10 sccm) greatly prolongs cell life without sacrificing fast response. The transducers are designed as 4- to 20-mA loop-powered instruments, allowing reduced cost, improved safety, and multipoint use.